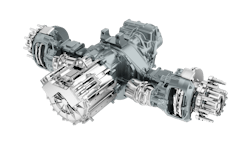

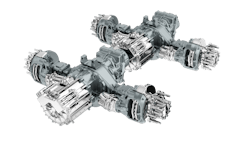

Dana Incorporated recently expanded its Spicer Electrified e-Powertrain offerings to include a family of single and tandem e-Axles designed for a wide variety of Class 7 and 8 applications.

The Spicer Electrified Zero-8 e-Axles complement Dana’s established heavy-duty electric vehicle (EV) e-Propulsion systems, which power “thousands” of vehicles around the world.

Zero-8e-Axles leverage Dana’s most robust and efficient drive axle technology, and are precisely engineered for demanding, over-the-road applications. The new e-Axle portfolio supports Dana’s approach to meet the diverse landscape of Class 7 and 8 EV architectures with multi-faceted electric powertrain solutions, including systems for direct drive, and now 4x2, 6x2, and 6x4 multi-speed e-Axle systems.

“Dana has leveraged its experience in global heavy-duty e-Powertrain systems to introduce a complementing family of e-Axles that offer maximum efficiency, performance and reliability,” said Ryan Laskey, senior vice president of commercial vehicle drive and motion systems for Dana. “These new product platforms utilize our proven, vertically integrated motors and inverters and provide our customers with improved packaging and efficiency for their electric vehicle needs. Our technical team is committed to providing our customers with the best purpose-built, zero-emission solutions.”

The new e-Axles are designed to easily integrate into most existing chassis. The platform utilizes Dana’s vertically integrated and long-standing technologies, including Dana TM4 motors and inverters, Spicer high-efficiency axle gearing, Graziano synchronizers, transmission controllers, system software, and shift system and controls.

The 4x2, 6x2, and 6x4 configurations are compatible with drum or disc brakes, and are available as completely integrated fully dressed assemblies. The e-Axles range from 52,000 Nm to 69,000 Nm of nominal output torque, and support gross axle weight ratings (GAWRs) from 21,000 to 30,000 pounds for single e-Axle configurations, and 40,000 to 52,000 pounds for tandem e-Axle propulsion.

Additional distinct features of the system are its modular motor design that provides easy accessibility for servicing and maintenance, and a motor interchange capability for increased ease of scalability in the Class 7 and 8 application range, further accommodating customers’ electrified platforms.

“These new e-Axles are predicated on our most sought-after, field-proven technologies,” Laskey added. “They are currently undergoing testing around the world in both battery-electric and fuel-cell applications and are ready for full-scale adoption as the commercial-vehicle segment continues to progress to fully electrified platforms.”

With global production strategies underway, Dana has commitments from global OEM customers with deliveries beginning in late 2023.