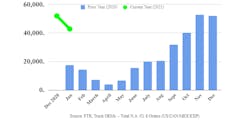

FTR reports preliminary North American Class 8 net orders for January remained elevated at 42,800 units.

January was the fourth consecutive month for Class 8 orders to exceed 40,000 units, FTR said. January order activity was -18% month-over-month and +144% year-over-year. Orders for the previous 12 months now total 308,000.

Freight growth remains vibrant and fleets are rushing to add capacity as fast as possible. OEMs and suppliers are trying to keep pace with the surging demand. Fleets continue to place orders out to the end of the year to acquire trucks as they become available.

“Currently there are shortages of raw materials and component parts, which will result in supply being unable to meet the demand of Class 8 trucks in the short-term,” said Don Ake, vice president of commercial vehicles for FTR. “Class 8 suppliers are working diligently to ramp up production but are hindered by the pandemic and material shortages. In addition, imported parts deliveries are being delayed up to two weeks at the ports.

“The supply chain is struggling after the surge in demand following the economic restart. Now companies are having problems hiring back enough workers due to virus concerns and protocols. Also, the steel plants took longer than expected to fire back up. Demand for Class 8 trucks is surging, but the supply chain is hindered.

“Our industry is very skilled and experienced in dealing with roadblocks. It will handle this situation better than other sectors. However, this will limit first-quarter production and will probably run over into part of Q2. When the vaccine enables employment to increase and the other bottlenecks are removed, this will end up being a robust year for Class 8 sales.”