Reports: Trailer orders tumble in May

U.S. trailer orders took an anticipated tumble in May, according to the latest data from industry analysts FTR Intel and ACT Research.

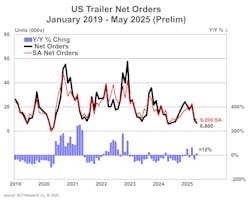

Net orders fell 34% month-over-month to 6,738 units, per FTR’s tally, which exceeded typical seasonal declines as tariff volatility and ongoing uncertainty in economic and truck freight markets persisted. Despite the decrease, May net orders were up 3% year-over-year, benefiting from comparison against a weak performance in May 2024. Year-to-date (YTD) net trailer orders for 2025 reached 83,218 units, a 24% increase year-over-year, averaging 16,644 units per month, FTR added.

Order cancellations surged to 37.6% of gross orders in May—the highest rate in 12 months and significantly above April’s 20% figure. Cumulative net orders for the 2025 ordering season (September 2024–May 2025) totaled 161,657 units, down 10% year-over-year, averaging 17,962 units per month.

During May, total U.S. trailer build fell 4% month-over-month and 24% year-over-year to 16,958 units. 2025 YTD trailer build was down 29% year-over-year to 80,729 units, an average of 16,146 per month. With total trailer net orders significantly below build, backlogs decreased by 11,376 units to 108,955 units. The larger decrease in backlogs compared to build lowered the backlog/build ratio to 6.4 months.

“The ever-evolving tariff environment continues to disrupt the U.S. trailer market,” Dan Moyer, FTR senior analyst for commercial vehicles, said in a news release. “The increase in tariffs on steel, aluminum, and fabricated components to 50% on June 4 will significantly increase production costs for OEMs/suppliers, putting further downside pressure on trailer demand. Also, while tariffs on Chinese imports have moderated greatly—at least temporarily—other country-specific tariffs add further cost pressures. A further headwind on demand is uncertainty over the legality of the reciprocal and fentanyl-related tariffs that were based on emergency powers.

“OEMs and suppliers face pressure to either absorb rising costs or pass some or all of them on to fleets, potentially impacting fleet expansion and maintenance strategies. As a result, some fleets may delay new trailer purchases or turn to refurbished and alternative options. Potential consequences include heightened market price sensitivity, extended trailer lifecycles, and a shifting of some demand toward used equipment or alternative configurations.”

Order intake remains subdued

Preliminary net trailer orders dropped more than 2,300 units from April to May, a contraction of about 26%, ACT reported. However, at 6,600 units, order intake was nearly 12% higher compared to May 2024. Seasonal adjustment (SA) at this point in the annual order cycle raises May’s tally to 9,200 units.

“Lower May net order intake was expected, as it is one of the weakest order months of the annual cycle,” said Jennifer McNealy, ACT director of CV market research and publications. “More concerning, though, is this level of order acceptance does nothing to support backlog growth, particularly with the elevated cancellation rates reported in the past several months.

“With weak for-hire truck market fundamentals, low used equipment valuations, relatively full inventories, high interest rates, and the ambiguity of policy shifts still in play, ACT’s expectations for subdued build and order intake levels during 2025 remain intact.”